Industry News

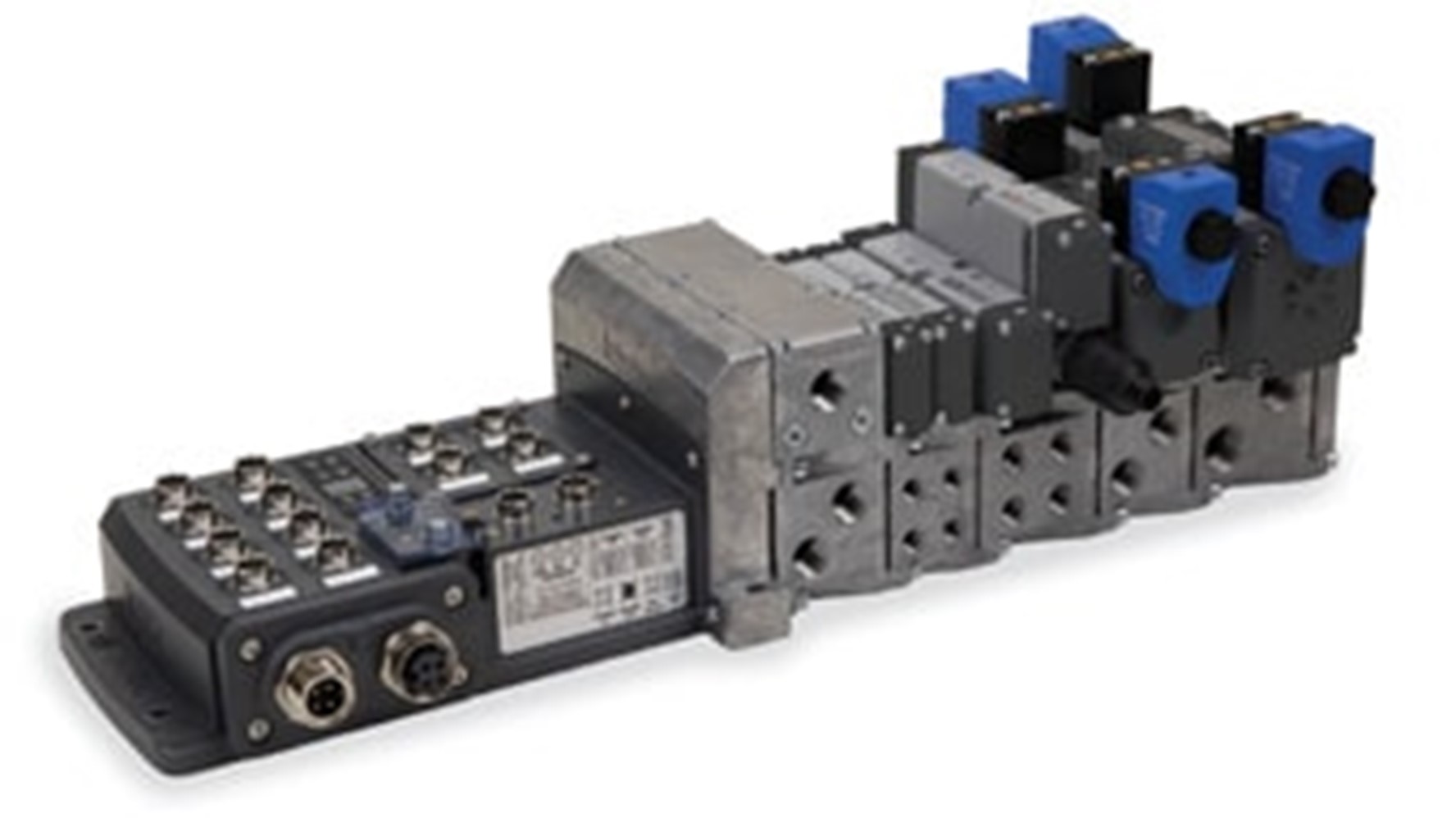

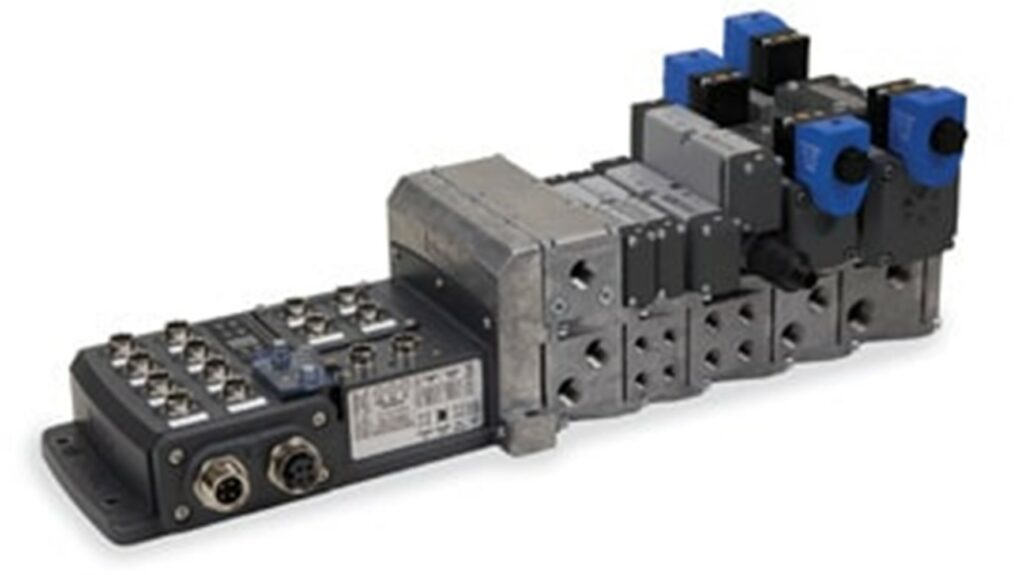

Parker Hannifin is releasing its PCH Network Portal in the European market. The product is a new approach to Ethernet communication modules that reformulates and transforms machine I/O architecture. With Industry 4.0 and IIoT based industrial networks increasingly taking advantage of Ethernet protocols and IO-Link communications, PCH Network Portal can help to minimise machine costs, start-up time and downtime across the factory automation market.

The Ethernet communication module meets user requirements at any period in the machine’s life, from conception and integration, through to production and maintenance requirements. Where most existing solutions are modular in design with fluctuating dimensions, PCH Network Portal integrates the versatility of its configuration into a single compact footprint to provide notable market differentiation.

Another important feature allows users to tap into the power of IO-Link, extending connectivity to remote IOs and limiting wired connections. The flexibility of IO-Link also allows users to set-up a connection port as a digital input (DI), digital output (DO) or IO-Link master port, bringing added value to applications that include material handling systems, vehicle body assembly, industrial assembly lines, end-of-arm tooling (EOAT) for robots and other automated industrial equipment.

Part of Parker Hannifin’s field bus/industrial network offer, the decentralised I/O and IO-Link master ports of PCH Network Portal pave the way to optimised machine architecture and higher levels of configurability – all while connecting to five sizes of the company’s H Series ISO valves.

PCH Network Portal can communicate with many industrial controllers as it supports EtherNet/IP, PROFINET, Modbus TCP and EtherCAT protocols. This capability makes it ideal for a number of flexible manufacturing applications, including: where machine changes are common; where PLCs are not always accessible; or where obstacles on the plant floor make set-up, configuration and troubleshooting time consuming.

Configurable I/O with true PNP/NPN circuitry switching and IO-Link on each port facilitate easy machine design changes. As a further advantage, built-in programming functions (such as de-bounce timers and time-stamped rolling 40 errors, warnings and events logs) make troubleshooting and integration easy, even for unexperienced programmers. Users can configure and troubleshoot via a laptop, tablet or phone with a secure and lockable Bluetooth® connection.

“Whether you are a system integrator looking to minimise machine costs, a controls engineer seeking shorter start-up times or a maintenance professional looking to decrease downtime, the flexible design, intuitive interfaces and streamlined diagnostics offered by PCH Network Portal will add value to your project,” said Patrick Berdal, European Product Manager, Parker Electric Motion & Pneumatic Division. “Companies operating within Europe’s factory automation market are currently busy helping manufacturing facilities transition to the production plants of tomorrow. PCH Network Portal can make that process easier, faster and more cost-effective.”

Able to operate in temperatures between -15 and +49°C, the PCH Network Portal features configurable IO-Link master ports inside an IP65-rated, weld splatter resistant housing to future-proof machines against network architecture changes.