Industry News

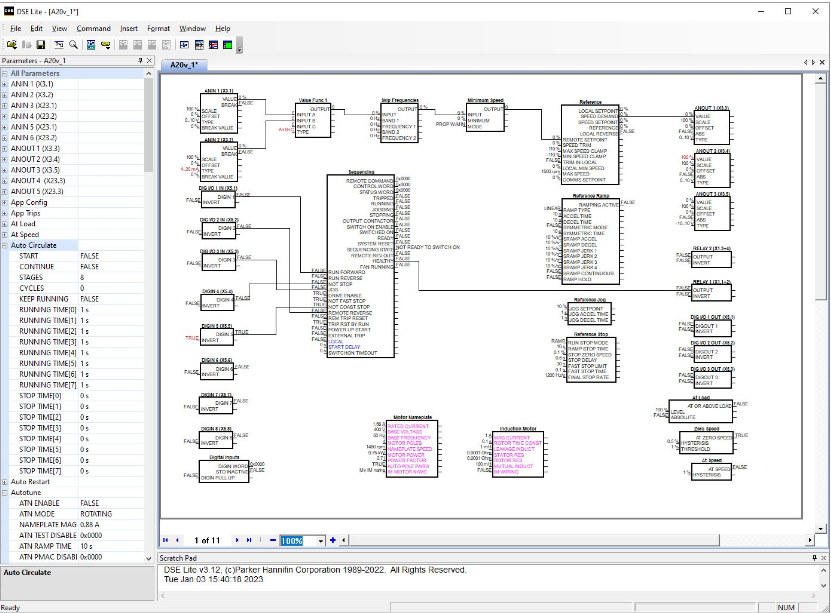

Inverter drives are essential for industrial automation, providing precise motor control, energy efficiency, and system flexibility.

Inverter drives are essential for industrial automation, providing precise motor control, energy efficiency, and system flexibility. While basic parameters like voltage, frequency, and acceleration are well-known, advanced parameter settings allow for greater performance optimization, system protection, and intelligent automation.

Understanding these advanced settings can help improve drive efficiency, reduce wear and tear, and enhance overall system reliability.

1. Auto-Tuning for Optimized Motor Performance

Modern inverter drives feature auto-tuning functions that automatically adjust drive settings based on the connected motor.

🔹 Why it matters?

✔ Ensures optimal torque and speed control

✔ Reduces motor heating and vibration

✔ Increases overall drive efficiency

💡 Tip: Auto-tuning should be performed after initial setup and whenever the motor or drive settings are changed.

2. Dynamic Braking for High-Inertia Loads

When an inverter drive needs to slow down a high-inertia load quickly, dynamic braking is used to dissipate excess energy.

🔹 Why it matters?

✔ Prevents overvoltage faults during rapid deceleration

✔ Reduces stopping time for faster cycle operations

✔ Prevents mechanical wear in braking systems

💡 Tip: Configure braking resistors properly to handle the energy dissipation without overheating.

3. Flux Vector Control for High-Performance Applications

Flux vector control is an advanced motor control mode that provides precise torque and speed control.

🔹 Why it matters?

✔ Maintains constant torque across varying speeds

✔ Reduces motor slip for improved accuracy

✔ Allows operation at lower speeds without losing torque

💡 Tip: Use sensorless vector control for high performance without the need for an encoder. For extreme precision, use closed-loop vector control with an encoder.

4. PID Control for Automated Process Optimization

PID (Proportional-Integral-Derivative) control is an automation feature that allows an inverter drive to maintain a setpoint without manual adjustments.

🔹 Why it matters?

✔ Helps regulate pressure, flow, or temperature in industrial processes

✔ Improves energy efficiency by adjusting motor speed automatically

✔ Reduces wear and tear on mechanical components

💡 Tip: Proper PID tuning is essential—incorrect settings can cause oscillations, slow response, or instability.

5. Flying Start for Restarting Spinning Motors

The flying start function allows the inverter drive to detect the speed of a spinning motor and smoothly match its frequency before taking full control.

🔹 Why it matters?

✔ Prevents motor shock and sudden surges when restarting

✔ Reduces stress on mechanical components

✔ Ideal for fans, pumps, and conveyor systems where motors may still be spinning when restarted

💡 Tip: Enable flying start in applications with frequent stop-start cycles to enhance system efficiency.

6. Torque Limit & Stall Prevention

Setting torque limits prevents excessive force on mechanical systems, protecting both the motor and connected equipment.

🔹 Why it matters?

✔ Prevents motor overheating and mechanical failures

✔ Reduces wear on gearboxes and belts

✔ Helps avoid unexpected drive shutdowns due to overloads

💡 Tip: Set the torque limit based on the motor and load specifications to prevent unnecessary system strain.

7. Skip Frequency to Avoid Resonance Issues

Some systems experience mechanical resonance at specific frequencies, causing vibrations and noise. The skip frequency function allows the inverter drive to bypass these problematic frequencies.

🔹 Why it matters?

✔ Reduces vibration and mechanical fatigue

✔ Extends the lifespan of bearings and other moving parts

✔ Improves stability in high-speed applications

💡 Tip: Identify resonance points using vibration analysis tools and configure the drive to skip those frequencies.

8. Energy-Saving Mode for Reduced Power Consumption

Many inverter drives have built-in energy optimization features that automatically adjust voltage and frequency to improve efficiency.

🔹 Why it matters?

✔ Reduces unnecessary energy consumption

✔ Lowers electricity costs in motor-driven systems

✔ Minimizes heat generation, reducing cooling requirements

💡 Tip: Use energy-saving mode in low-load conditions but ensure it doesn’t impact performance in critical applications.

9. Multi-Speed Settings for Variable Applications

Instead of relying on an external controller, inverter drives can store and switch between multiple preset speeds for different operating conditions.

🔹 Why it matters?

✔ Ideal for applications with varying speed requirements (e.g., conveyors, pumps, and mixers)

✔ Reduces wear and tear by avoiding excessive acceleration/deceleration cycles

✔ Simplifies automation without needing complex external PLC programming

💡 Tip: Configure multi-speed settings for applications requiring preset speeds rather than continuously variable control.

10. Communication Protocols for Network Integration

Many inverter drives now support industrial communication protocols for seamless integration into automation and SCADA systems. Common options include:

🔹 Modbus RTU / TCP

🔹 Ethernet/IP

🔹 Profinet / Profibus

🔹 CANopen

🔹 Why it matters?

✔ Enables remote monitoring and control

✔ Allows for data logging and predictive maintenance

✔ Integrates with PLCs and factory automation systems

💡 Tip: Choose a drive that supports your existing communication infrastructure to maximize compatibility.

How SDS Drives Can Help

At SDS Drives, we specialize in optimizing inverter drive performance through:

✔ Advanced drive programming and configuration

✔ Training for maintenance teams on parameter tuning

✔ Troubleshooting and fault diagnostics

✔ Loan Drive Services to keep operations running during maintenance or repairs

Conclusion

Advanced inverter drive parameters unlock powerful capabilities that enhance performance, efficiency, and system reliability. By understanding and fine-tuning these settings, businesses can reduce downtime, improve automation, and extend equipment life.

👉 Need expert support with drive setup and optimization? Contact SDS Drives today for professional assistance!